Resourceful and Reliable

Custom Materials

Our ability to laminate, form, and cut multiple material combinations provides a vast number of possible solutions. Films, adhesives, plastics, felts, foams, and other specialty materials can be converted into shims, spacers, gaskets, filters, insulators, shields, and more.

Precision Manufacturing

With several forming and cutting technologies we can meet even the most precise requirements. Whether it is high or low volume, we can develop the correct process and controls to ensure quality products every time.

Ultra-responsive

We recognize business moves quickly. The need for quick prototypes, short lead-times, and responsive support are key to why manufacturers choose Inno-Flex. Whether it is a last minute fix or an accelerated project schedule, we have you covered.

Thermoformed Graphics

Leveraging our printing and forming expertise, Inno-Flex can provide vacuum thermoformed graphics with vivid colors and accurate 3D alignment for durable emblems, decorative inserts, vending machine overlays, and POP signage.

Thermal Interface Materials

To address the thermal demands of today’s electronic devices, Inno-Flex provides customized solutions for thermal interface materials. Whether you are removing heat from a circuit board or LED, bridging the gap between heat sinks and housings, or managing heat between battery cells, we have the capabilities to provide a custom solution to meet your requirements. We utilize a multitude of thermal interface materials to custom laminate, cut, and deliver solutions for your products that are easy and efficient for your manufacturing lines.

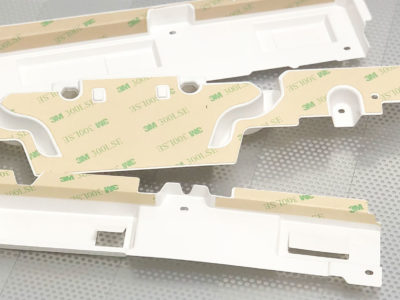

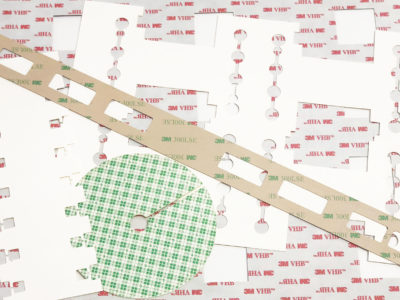

Die Cut Industrial Adhesives

Industrial tapes and adhesives play a versatile role in manufacturing. Our ability to custom convert a wide range of adhesives helps customers bond, seal, and join different materials to streamline production. Our solutions can replace mechanical fasteners and welds, reduce vibration and noise, reflect heat and light, and solve a number of other product design challenges.

Thermoformed Shielding

Today's electronics face harsh conditions. Whether it is exposure to moisture, high heat, or human hands, shielding can be used to protect printed circuit boards and other electronic components. Thermoformed shields match the contour of individual components to effectively protect electronics from dust, debris, and liquids. In addition, printed conductive circuitry can be added to our shields to create ESD and EMI/RFI protection.

Electrical & Thermal Insulating Materials

Inno-Flex has the materials and capability to design and manufacturer many different types of electrical and thermal insulation solutions. Through thoughtful material selection and creative process design, we provide custom solutions to shield, insulate, or protect your electrical products.

Gaskets

We design and manufacture custom precision gaskets using a variety of different foam, rubber, and adhesive materials. Customize the layers to get the exact outcome you desire.