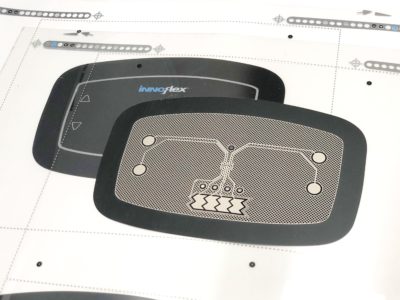

In-Mold Electronics

In-Mold Electronics leverages the benefits of printed electronics and in-mold decorating to create smart surfaces and 3 dimensional user interfaces. A multi-layer construction includes both graphics and electronic circuitry that is permanently fused to plastic during the in-mold decorating process. This creates an integrated touch interface that reduces cost, components, and complexity. Best of all, it provides manufacturers with the futuristic touch interfaces their customers want.

Connect with Our Engineers to Learn MoreIn-Mold Electronics Process

From flat film to functional part

Graphics and circuitry layers are printed on a flat polymer film.

Form

Printed film is precision formed to a three dimensional shape that mirrors the final molded part.

Mold

Final part is created by injection molding the formed film using the in-mold decorating process to add structure and electrical connections.